Lean HR Recipe – What Ingredients do you need?

So you are looking to make your HR processes lean, what are the main ingredients of this recipe?

Ingredients:

1 Manager/Process owner

1 Engaged Team (all main stakeholder groups represented)

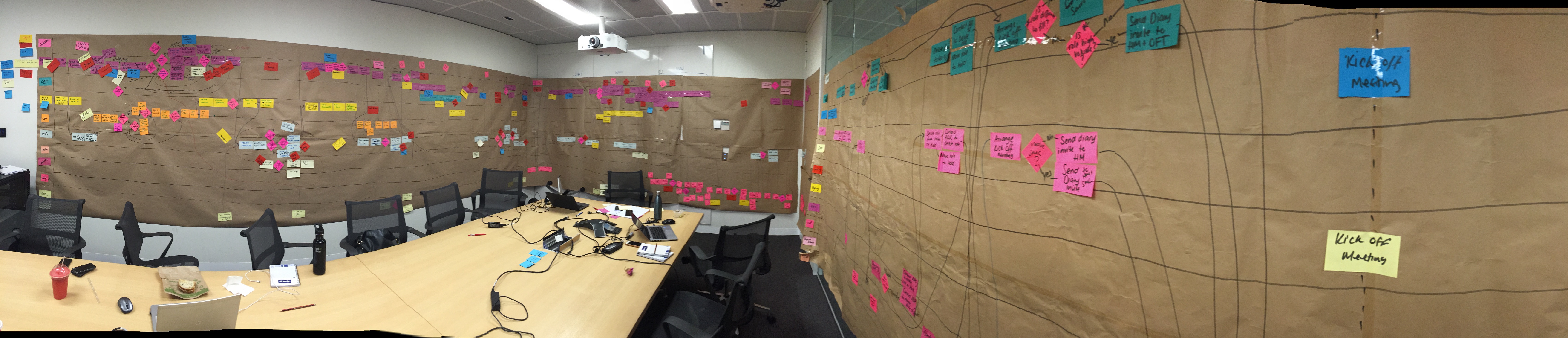

1 roll of Brown Paper

2-3 packs of coloured Sticky Notes

2 packs of coloured sticky dots

1-2 Files of sample Data

1 pack of blue tack

2-3 pens

1 Flip Chart with paper

Cooking Time: 2-3 hours

Recipe Prep:

Analyse data to understand where there may be issues, bottlenecks and waste.

Take Roll of Brown paper and stick to the wall with blue tack

Draw swim lanes on the brown paper to indicate the different position/stakeholder groups involved in the process (eg Recruiters, HRBP, Finance, HRadmin etc)

Preheat the engagement of the team and stakeholders to 180c, by explaining the structure of the workshop and benefits.

Many of these people live this process day in day out, and may get a little hot under the collar, you may need to be fan assisted.

Method:

Ask the group what is the first step of the process, and who does this action?

Write on a sticky note and place on relevant swim lane. Ask what is the next step, and note down again. Complete this for all steps until you have a nice and congested process map.

Ask workshop members to take 6 red sticky dots and season generously the map, where they feel the waste and issues in the process are, with 3 red dots on the action/task with the most waste, 2 red dots on the next issue, and finally 1 red dot on the action that is the third biggest issue.

At the end, you will have a map littered with red dots. If further seasoning is required to ascertain the issue, repeat the exercise. Once the red dots have been distributed, spend some time talking through the results and discuss why the group thinks these are issues.

At the end, you will have a map littered with red dots. If further seasoning is required to ascertain the issue, repeat the exercise. Once the red dots have been distributed, spend some time talking through the results and discuss why the group thinks these are issues.

Looking at the map, ask the group which tasks can be improved or removed. You’ll be surprised how many tasks are wasted time, effort or cost. At the end of the workshop you will have identified the areas that you will want to improve or remove and create a new lean process.

Next you will need to spend some time discussing the improvements and how to implement them. Then you will need to measure the new process, to see the new positive results and compare it against the original data that you captured.

Next you will need to spend some time discussing the improvements and how to implement them. Then you will need to measure the new process, to see the new positive results and compare it against the original data that you captured.

If you liked this Recipe, please share.

For other definitions on waste see DOWNTIME.